10 Best Bar Clamps 2023 – Reviews & Buying Guide

-

- Last updated:

Most tradesmen know that they never have enough bar clamps. They are used to keep materials in place while welding, joining, and otherwise fastening two or more pieces. A single job can require dozens of clamps. As such, you will want something cost-effective, but you shouldn’t overlook specific factors like material used in the clamp’s construction and available bar sizes.

You will want to ensure that it has a smooth sliding mechanism, robust build quality, and a solid general feel.

Many bars have additional features like double locking systems or soft-grip handles. With different clamps available from suppliers including Irwin, DeWalt, Jorgensen, and Tekton, there is a large selection of clamps for you to choose from.

We have written reviews of the 10 best bar clamps so that you can decide which one best meets your requirements and those of your current project.

A Quick Comparison of Our Favorites in 2023

| Rating | Image | Product | Details | |

|---|---|---|---|---|

Best Overall

|

|

TEKTON 39185 Ratchet Bar Clamp |

|

CHECK PRICE |

Best Value

|

|

IRWIN 1964758 QUICK-GRIP Clamps |

|

CHECK PRICE |

Premium Choice

|

|

Jorgensen 123ABC Jaw Bar Clamp |

|

CHECK PRICE |

|

|

|

Bessey GSCC2.536 Clutch Style Bar Clamp |

|

CHECK PRICE |

|

|

|

Yost 15036 Bar Clamp |

|

CHECK PRICE |

The 10 Best Bar Clamps

1. TEKTON 39185 Ratchet Bar Clamp – Best Overall

The Tekton 39185 Ratchet Bar Clamp is a low to mid-price bar clamp. Available in sizes from 6 to 36 inches, the bar is made from carbon steel and the jaws from reinforced nylon. The jaws have a sure grip but are soft enough that they won’t damage the workpiece.

The small assembly can be used even in tight spaces, and the quick-release button makes it easy to remove, although it is quite small and can take some time to find. The fixed jaw can be moved to the opposite end of the bar, too, converting the clamp to a spreader, if you need to separate pieces.

There have been some reports of the plastic mechanism snapping under heavy use, although these reports are minimal, so if you need something heavy-duty, you will need to look at more expensive clamps. The quick-release button and pressure handle are the opposite of what many users will be used to. However, for the money, and considering the Tekton’s ease of use, these represent the best overall value.

- Convert to a spreader

- Quick-release button

- Nylon jaw won’t damage the workpiece

- Cheap

- Not suitable for heavy-duty applications

2. IRWIN 1964758 QUICK-GRIP Clamps – Best Value

Irwin is well-known for manufacturing high quality, affordable clamps, and these Irwin Quick-Grip Clamps are no different. The 6-inch mini clamps come in a pack of four and cost a little more than most companies charge for a single clamp. Despite their low cost, they are made from hardened steel bars and reinforced resin bodies. The clamps stay firmly in place, and they grip tightly without leaving a mark on surfaces.

Designed for one-handed use with quick release triggers, the Irwin Quick-Grip Clamps offer 140 pounds of clamp pressure, which should be more than enough for virtually all jobs. These clamps do not operate as spreaders, and while they do offer a lot of clamp strength, they aren’t heavy duty and will lose pressure over time. However, their low price, solid manufacturer reputation, and their strong clamping ability make them the best bar clamps for the money.

- Cheap

- Minimal slippage

- Quick-release trigger is easy to use

- Very difficult to remove from packaging

- Not designed for heavy-duty use

3. Jorgensen 123ABC Jaw Bar Clamp – Premium Choice

The Jorgensen 123ABC Jaw Bar Clamp is expensive, but it has a selection of valuable features that will make them invaluable for certain jobs. They have deep jaws, which allows for greater pressure distribution across the body, enabling a firmer grip and preventing slippage. The sides are precisely parallel, which makes them suitable for 90° clamping.

The handles are ergonomically designed and have a soft grip coating so they are comfortable to use. The jaws are made of plastic, although they are steel-reinforced, plastic is likely to become brittle over time.

Overall, these clamps have a very strong and robust feel to them and, although they are more expensive than most, and the plastic jaws are a little disappointing at this price point, they will withstand heavy use a lot better than other models. Jorgensen is a very well respected clamp manufacturing brand.

- Parallel once clamped

- Soft grip handles are comfortable

- Steel reinforced handles

- Deep jaws

- Plastic handles may become brittle

- Expensive

4. Bessey GSCC2.536 Clutch Style Bar Clamp

Bessey GSCC2.536 Clutch Style Bar Clamps are simple and cheap, but surprisingly strong and effective for the price. The 2-piece clutch plate system is not as easy to use as a pistol grip lock, but it makes the clamps less likely to break. The powder-coated finish and zinc finished rail is tough and durable, but with the 36-inch model, there is some bowing when the bar is fully extended and pressure applied. If you need something stronger, you will need to invest in heavy-duty bar clamps or pipe clamps.

The protective pads on the clamp head do a good job of preventing damage to the workpiece, while the wooden handle is comfortable even when applying a lot of pressure. Unfortunately, there are some issues with quality control, with some reports of bent bars or other manufacturing issues.

- Cheap

- Good grip

- Durable

- Some bowing at full extension

- Quality control issues

5. Yost 15036 Bar Clamp

The Yost 15036 Bar Clamp is a steel bar clamp that offers an impressive 330 pounds of clamping pressure. The company boasts that this is 10% more than its competitors offer. The clamp can also be quickly turned into a spreader by emoving the stationary jaw and placing it on the opposite end of the bar. The nylon jaw is designed to be strong, applying precise pressure while the soft jaw covers prevent damage from being done to the workpiece or material that you are working on.

This is another clamp that has a quick-release button and uses the lever for applying pressure. This is the opposite of a lot of designs, and it may take some getting used to if you have used other clamps in the past.

- 330 lbs of clamping pressure

- Can be easily converted into a spreader

- Decent price

- The quick-release button will take some getting used to

6. WEN Quick-Adjust Steel Bar Clamps

This two-pack of 36-inch clamps from WEN includes two clamps with a quick-adjust design. This means that the clamp can be slid closed. This does make closing the clamp easy, but it takes a lot of work to open the jaws again after use. The clamps have a micro-adjustment knob that allows for tiny adjustments and lets you add extra pressure to ensure a tight close.

600 pounds of clamping pressure ensures a stable and secure fit, while the non-marring pads prevent damage to the work surface material. These bars are cheaper than a lot on the list, and they do provide a lot of clamping pressure for the money, but the sliding and adjustment mechanism are challenging to use and may cause a few scraped knuckles along the way.

- Lots of clamping pressure

- Micro-adjustment knob

- WEN is a respected name

- Difficult to open

- Some bowing under full extension

7. POWERTEC Quick Release Bar Clamp

The Powertec 71540 Quick Release Bar Clamp is a simple and inexpensive bar clamp. Available individually or sold in packs of two, these clamps come in 6, 12, 24, and 36-inch sizes. Made from carbon steel, the bar is less likely to bend, but the plastic clamp heads do tend to break or snap off.

The clamps are lightweight, which is great for convenience and ease of use, but it means that they shouldn’t be used for heavy-duty work. These are inexpensive and they should prove strong enough for light to medium jobs, but you should look elsewhere for heavy-duty and commercial projects.

- Cheap

- Convert to spreaders

- Quick-release

- Lightweight

- Not suitable for heavy-duty tasks

8. DEWALT DWHT83195 Bar Clamp

The DeWalt DWHT83195 Bar Clamp has been designed for use on construction sites. It has a glass fiber-reinforced nylon body. This is designed to be tough and offers decent impact resistance so should withstand the frequent knocks and bumps that it will endure while being used on a construction site. It is also finished in a bright yellow high-visibility coating, so it will be easy to find among the dust and dirt.

The pads, which prevent marking and scarring of workpiece material, can be removed and replaced.

The DeWalt bar clamps aren’t cheap, have a narrow throat, and while the pads can be replaced, it isn’t easy to find replacements, negating the benefit of this feature. Also, while the product claims to have 300-pound clamping pressure, the bar is flexible under load and will bow especially when used at full extension.

- Easily visible

- Replaceable pads

- 300 lbs of clamping pressure

- Pads are difficult to find

- Bar bows under pressure

- Not cheap

9. Shop Fox D2528 Jaws Aluminum Bar Clamp

The Shop Fox D2528 Jaws Aluminum Bar Clamp is a 36-inch bar clamp. The clamps are made from aluminum and the whole clamp is lightweight, only really suitable for light-duty tasks. They aren’t the most expensive, but they are far from being the cheapest clamps on our list, which makes their poor strength even more disappointing. They are available in 24-inch and 36-inch models and have plastic ends that are designed to prevent the handle from falling off.

The clamp pads are loose-fitting, which means that they are prone to coming off or having dust gather below them and preventing them from clamping tightly. Considering the price of these Fox Shop D2528 Jaws Aluminum Bar Clamps, they are not durable or effective enough to recommend, and better alternatives exist.

- Light and easy to maneuver

- Clamp faces run to the bar

- Not cheap

- Loose-fitting clamp pads

- Aluminum is not durable

- Bar bows under full extension

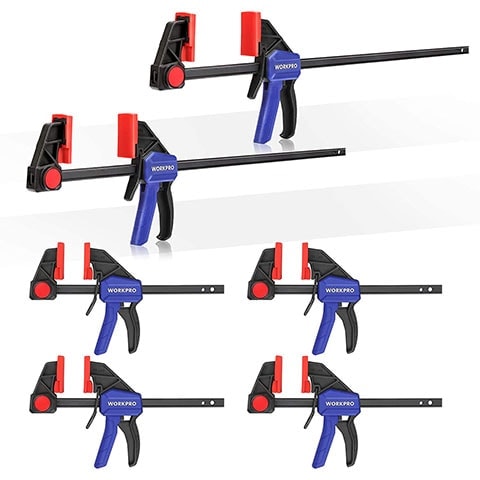

10. WORKPRO W001411A Bar Clamps

Workpro W001411A Bar Clamps are cheap, no-frills bar clamps. Available in a pack of six, the clamps have a hardened steel bar and reinforced nylon body. The clamp can be converted into a spreader, too, by pressing the release button, removing the fixed jaw, and placing it at the other end of the clamp bar. The clamps offer 150 pounds of force and they have removable and replaceable pads although, again, it is difficult to find replacement pads, which essentially negates this benefit.

A set consists of 4 x 6-inch bar clamps and 2 x 12-inch bar clamps. Although the set is quite cheap, the clamp caps tend to pop off, the replaceable parts are difficult to locate, and the clamping pressure is much less than with alternative products.

- Cheap

- Comes as a set

- Replaceable parts are difficult to find

- Only 150 pounds of force

- Clamp pads pop off easily

Buyer’s Guide – How to Choose the Best Bar Clamps

Bar clamps, which are also referred to as F-clamps, are a simple design of clamp. They have one fixed jaw and one movable jaw. Different mechanisms are used to tighten and loosen the clamp, but this type of versatile clamp can be used for anything from woodwork to light metalwork. And, can you ever have enough clamps?

When choosing a bar clamp, consider the following factors to ensure that you get the best clamp for the job at hand.

Materials

As with any tool, the choice of material is important. Lightweight materials are obviously lighter which makes the tool easier to lug around, while heavy-duty materials are more durable, last longer, and, with clamps, can be used to apply more pressure without bowing and bending. There are two main components to a bar clamp:

- Bar – In most cases, the bar of the bar clamp is made from steel, either hardened or carbon steel. Steel is a tough and durable material. It is unlikely to bow and bend even when under a lot of pressure, but it is heavy and can rust. A small number of clamps use aluminum as the bar material. Aluminum is light, but it is only suitable for lightweight tasks because it can bend and fold very easily.

- Body – The body of the clamp is the section that attaches to the bar and slides up and down it. This section is usually made from reinforced nylon, but may also be made from a hardened resin. In both cases, the material is chosen for its robust build, but you may want to ensure that the handles have a softened grip or additional soft layer, because nylon and resin can be hard, sharp, and abrasive, especially when you have to apply pressure.

Length

Bar clamps vary in length from 6 to 36 inches, although longer clamps are available for specialized jobs. The size you need is determined by the job at hand and the size of the workpieces that you need to clamp together.

You should also consider the throat depth. The bigger the throat, the further onto the workpiece you can place the clamp pads. Typically, this will give you greater stability and prevent any movement from the pieces, when working. However, if your workpieces are very narrow, you will need a small throat size to prevent the clamp from swinging around when in place.

Mechanism

There are different styles of mechanism used to tighten a clamp against the workpiece. The simplest method of tightening a clamp is using the strength of your hand alone. You squeeze the clamp as tightly as possible and then pull a trigger to lock it in place. Some clamps have an additional clamp. Once you have tightened the clamp as far as possible, using your hand, you lock it and then use the screw to apply additional pressure. This extra pressure helps ensure that the clamp remains firmly and tightly closed. If it is essential that your workpieces remain tightly sealed while using the clamp, look for one with this additional screwing mechanism.

Quick Release

As well as the mechanism used to tighten the clamp, there is a mechanism that is used to release the clamp. The majority of clamps use a quick release, although some do rely on hand strength alone.

A quick-release mechanism enables you to pull a trigger or press a button and this releases the clamp bod’s grip on the bar, loosening and essentially undoing the clamp for easy removal. A quick-release grip is the most common mechanism, and those clamps that use a button can cause confusion with users that are accustomed to a trigger mechanism.

Spreader Conversion

Some jobs demand that two or more workpieces be kept a specific distance apart during the fixing or gluing process. A spreader allows for exactly this. You can keep two ends of a frame, for example, parallel while the glue sets in the corners. This ensures a square finish.

Rather than having to buy separate clamps and spreaders, some bar clamps can be quickly and easily converted into spreaders. The fixed end of the clamp is removed and placed on the other end of the bar. The movable end can then be closed or opened, using the same mechanism as the caping mechanism, allowing for precision finishes.

Clamping Pressure

Some manufacturers list the clamping pressure of a bar clamp. This is the amount of pressure that is applied, and the greater the pressure, the less chance there is of movement. Pressure is weighed in pounds and is the equivalent of placing this much weight on top of one of the workpieces. The typical clamping pressure can vary from 150 to 600 pounds.

Too little clamping pressure means that your pieces will move around while you work on them, or they will simply slide out of the clamp’s jaws. Too much clamping pressure could cause damage to the workpiece, although this can be counteracted by loosening the clamp.

Soft Pads

The jaws of the clamp sit around your workpiece, and the pads of the jaw will sit directly on the wood or other material. If the pads are abrasive, sharp, or too hard, they can cause damage, often irreparable damage, to the piece you are working on. Look for clamps that have softened pads to prevent this damage from occurring.

You may also see some clamps with replaceable pads, but for this to be considered a benefit, the replacement pads need to be easy to find and purchase. This isn’t always the case, and many buyers have found that they have to order a brand new clamp because their hunt for replacement pads was unsuccessful.

Conclusion

Bar clamps are versatile and beneficial tools for the woodworker or metalworker. They find use on construction sites and in workshops but are also commonly used at home. They need to be good quality to ensure that they offer a strong enough grip, but they should not cause damage to a workpiece. Look for clamps that are made from steel and have a hardened nylon body with a soft grip surface. A quick release mechanism is convenient, while the ability to convert a clamp to a spreader negates the need to look for individual items. With so many models to choose from, we hope that our reviews help you get the clamp that best suits your next project. We found that the Tekton 39185 Ratchet Bar Clamp offered the best combination of strength, clamping pressure, price, and versatile features. Despite being one of the cheapest models available, the Irwin 1964758 Quick-Grip Clamps were easy to use, once you get them out of the packaging, and surprisingly strong.

Also, we have a guide for pipe clamps found here.

Contents