20 Different Types of Chisels & Their Uses – Which is Right for You?

-

- Last updated:

Chisels cut, shape, carve, and chip away at various materials. They’re incredibly useful and among the most versatile instruments in any tool kit. But one chisel isn’t made for every task, and you may need several if you’re working on numerous projects. To help you determine which tools you need, we’ve gathered the 20 different types of chisels that you need to know about if you’re serious about your craft. From woodworking to masonry, these chisels can be used in almost every setting imaginable.

The 20 Different Types of Carpentry Chisels

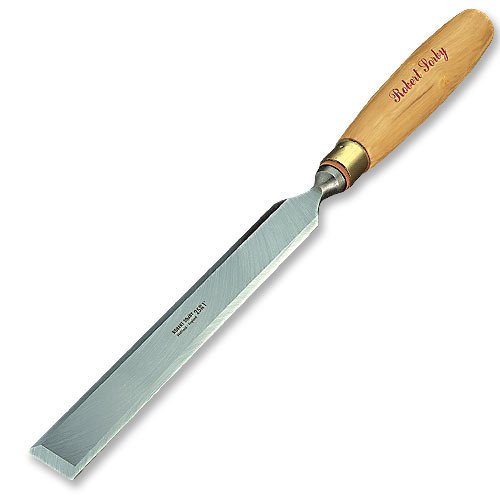

1. Paring Chisels

Unlike most chisels, you shouldn’t hit your paring chisel with a mallet. They are thin, long, flexible chisels that are meant for shaving off tiny amounts of wood to create precise-fitting joints.

2. Mortise Chisels

Mortising chisels are made to create a special hole called a mortise. A mortise is made for a tenon joint, and the holes are square or rectangular so that an interlocking piece (the tenon) will fit.

These chisels are made thick and strong so that they can withstand the hard hits it takes to make a hole in solid wood. Luckily, you don’t need these chisels in a wide range of sizes. One or two should do, with ¼-inch and ⅜-inch being the most common sizes.

3. Framing Chisels

Framing chisels are large, heavy-duty tools intended for making deep cuts in wood. They’re meant for the heaviest woodworking, so they’re built extra-durable with reinforced handles that can take repeated heavy blows without mushrooming or splitting.

4. Sash Mortise Chisels

Similar to a standard mortise chisel, a sash mortise chisel is made for cutting mortises. Unlike a regular mortise chisel, the sash mortise is meant for cutting shallow mortises, limiting its usefulness. Unless you need this particular feature, you probably won’t need a sash mortise chisel.

5. Skew Chisels

Skews are long, beveled-edge chisels that have angled tips. The long point of the tip is called the toe, and the short point is called the heel. They are great for smoothing and beading or creating tapers on a spindle. The skew chisel is also the best choice for V-cuts and beads.

They’re made for advanced woodworking techniques and are considered to be some of the most dangerous chisels to use because of their sharp tips. They can also easily gouge your wood, so they require great care.

6. Butt Chisels

These are very stubby, short little chisels that are made to work with butt hinges. You might find other uses for them, but they’re the perfect tool for installing the hinges. You’ll need them to carve away at the edge of your door so the hinge can lay flush inside the depression.

7. Slick Chisels

Slick chisels are paring chisels on steroids. They’re great for paring thin bits of wood off of large pieces such as logs. These chisels are very large with a handle that’s shaped like a baseball bat, making them easy to hold and comfortable to work with.

8. Bench Chisels

Bench chisels are so named because they typically sit on the bench rather than accompany you in your pocket or tool belt. They are multi-purpose chisels that can shape wood in various ways.

9. Beveled Edge Chisels

Beveled-edge chisels are the most common and versatile types of chisel for woodworking. They’re comfortable to hold with hardened butts that are meant for hitting with a mallet so you can shape wood, though they can also be used by hand for detailed work. They can do everything from rough work to finely finished work, making them a must-have for any woodworker’s tool collection.

10. Dovetail Chisels

Dovetail joints are a type of strong interlocking joint that’s commonly used in woodworking. Dovetail chisels are specially shaped to create these joints by hand. They can also be used to clean up joints that you cut with a machine.

11. Curved Chisels

If you look at the tip of a curved chisel, it is U-shaped, running down the length of the blade. This allows a curved chisel to remove more material in a single pass, making for faster, more efficient shaping. They’re also often used for carving complex shapes into wood.

12. Lathe Chisels

A lathe is a woodworking machine that spins the piece of wood you’re working on. Lathe chisels allow you to shape the wood while it spins by holding them against the wood to remove the material with each pass.

Masonry Chisels

13. Masonry Chisels

Masonry chisels are specifically made to work with stone, bricks, concrete, and even harder materials. You can gently score the surface of these materials with a masonry chisel and snap off the line with a harder tap once scored all the way across.

14. Concrete Chisels

Unlike most chisels, concrete chisels come to a point at the tip instead of a flat blade. They’re durable tools with a wide butt meant to protect your hand when swinging hard with a mallet or mini-sledgehammer. These chisels can score concrete or even cut through it. They’re perfect for demo tasks that require the use of a finer tool than the likes of a jackhammer, hammer drill, or demolition hammer.

15. Brick Chisels

The brick chisel is also known as a bolster chisel. They’re meant for cutting straight sides on bricks, and they’re a variation of the standard masonry chisel. You don’t want to use a brick chisel on anything but brick. Doing so will ruin the edge and make it difficult to cut bricks.

16. Stone Chisels

As you might guess from the name, this chisel is meant for use in stone. Since stones like granite are extremely hard, stone chisels are made of hardened steel that can withstand the abuse. But they’re not just a tool for blunt force. On the contrary, the stone chisel is used for creating sculptures of fine art.

Metal Chisels

17. Cold Chisels

Cold chisels are one of the few hand tools made for working with metals. These are made of steel that’s hardened, so it’s even more durable. They can be used to cut any material that’s softer than the chisel, making them great for cutting off rivets or rusted bolts.

18. Cape Chisels

Cape chisels are special cold chisels with long, tapered blades. They’re perfect for creating details and art in metals by carving tiny grooves into the surface.

19. Gouge Chisels

The gouge chisel has a curved blade like a half-moon. They’re meant for cutting round or semi-circular grooves in metal.

Specialty Chisels

20. Power Chisels

Until now, all of the chisels on this list resembled the basic chisel that we all know. But power chisels are a purely modern invention. These chisels are powered by a motor, giving them far more power and accuracy than you can get while hitting a hand tool with a hammer. When you need some serious power behind your chisel, the power chisel is ideal.

Frequently Asked Questions Regarding Chisels

How Long Have Humans Been Using Chisels?

Chisels are one of the earliest tools that ancient humans developed. The earliest ancestors of the modern-day chisel were made of flint. These early chisels date back to 8,000 B.C.E., which means that humans have been using these tools for more than 10,000 years!

What Are Chisels Used For?

Chisels might seem like fundamental tools, but they can be used for a wide range of uses. They can be used to chip away at different materials, but they can also do much more than that. These tools can be used to shape and carve just about anything. In fact, some of the most impressive pieces of art in the world are statues that were carved with chisels.

What Kind of Materials Can A Chisel be Used With?

Chisels are versatile tools that can be used in a variety of mediums. You can use them with all types of wood, including plywood and medium-density fiberboard (MDF), though both of those are likely to splinter and fall apart under the impacts. There are also chisels made for working with masonry. You can use chisels with stone, metal, and just about any material you can think of.

What is Dressing a Chisel?

Chisels take a lot of abuse. After repeated hits on the butt end of the chisel, you’ll start to see it spread out, getting fatter and flatter. This is called mushrooming because the butt of the chisel takes on a mushroom shape once it spreads out.

Unfortunately, a mushroomed chisel can be dangerous. The mushroomed end is weakened and liable to break off and go flying. Dressing is the process of removing the mushroomed head by grinding down the edges until they’re flat again. For a complete guide on how to dress a chisel, check out this video.

Can You Sharpen a Chisel?

You may not realize this, but using a chisel with a blunt tip is dangerous. Naturally, as the tip is continually beaten into hard materials, it loses its sharp edge. It takes greater and greater force to get the same effect, leading you to hit it harder and harder. As you swing the hammer harder, your risk of injury increases since you’re much more likely to slip or miss when banging the chisel so hard.

How Do You Sharpen a Chisel?

There are several ways to sharpen the tip of a chisel. Some require special tools, and others you can perform with items that are probably already in your workshop.

Sandpaper

If you have a workshop or garage full of tools, you most likely have some sandpaper. Luckily, that’s all it takes to sharpen your chisel. Check out this video to learn how.

Whetstone

Whetstones are common tools that sharpen metal blades, including the tip of a chisel. It’s a simple process involving dragging the edge of the chisel’s tip against the whetstone and shaping it. To learn the exact steps to take, check out this short video.

Grinder

If you have a bench grinder, you can easily sharpen many types of chisels in just a few minutes by shaping the edge on the grinder. This video will give you the lowdown on exactly how to do it.

Conclusion

As you can see, there’s a chisel explicitly made to complete practically every task in construction work. These tools can be used with almost any material, from wood to masonry, metal, and beyond. They’re one of the first tools that humans ever invented, and they’ve been in use for more than 10,000 years, yet they’re still one of the most valuable tools you’ll add to your collection.

With the guide that we have presented today, you should have no trouble selecting the right products for your exact needs.

See Also:

Contents