Cut-Off Tool vs Angle Grinder: Which is Best for Your Needs?

-

- Last updated:

Though cut-off tools and angle grinders may look similar, they have key differences that can significantly affect how well they perform some jobs. They aren’t interchangeable. Instead, you should carefully consider which tool you need for the job. However, that is often easier said than done. Below, we’ll discuss cut-off tools and angle grinders to help you determine which tool is best for your purposes.

Overview of Cut-Off Tools

Cut-off tools are small, single-handed tools that cut or sharpen metal pieces. They usually have around a 1 HP motor and have a cutting disc aligned at a right angle. Because of this design, they are not made to be used on thick pieces of metal. Instead, they are best for cutting through very thin pieces.

However, the tool’s lightweight causes less fatigue. Cut-off tools are also straightforward to control and can be used with one hand. They are also very affordable because their design is pretty simple. They don’t need a powerful motor, which keeps the prices down.

How a Cut-off Tool Works

Most cut-off tools come with a small disc that is usually no more than 3 inches in diameter and is best suited for small workpieces and spaces. Its small size makes it easy to use in smaller spaces where other tools might not work.

Cut-off tools can be powered by electricity or air pressure, and some battery-powered models are also available. However, they are exceedingly rare and not very powerful in most cases. Pneumatic brands are the most powerful and are very common in automotive shops for this reason.

Electric-powered models are only best for minimal jobs. While they are bigger, they are generally not as powerful. Of course, they don’t require that you use an air compressor with them, which may be a plus for some buyers.

- Small and compact

- Inexpensive

- Precise

- Can be used with a single hand

- Many different options available

- Only suitable for very light jobs

Overview of Angle Grinders

An angle grinder is very similar to a cut-off tool. It is designed to be portable, but it is still slightly larger than a cut-off tool. Therefore, it may not be as suitable for smaller spaces. Their motor is typically heavier and produces between 3–7 HP.

The grinding disk is also large, and you can find options measuring 4.5–9 inches. Because of the larger design, the angle grinder is best for heavier applications where you must cut through thick metal pieces.

How Angle Grinders Work

Usually, the cutting disc is positioned so that it is at the same angle as the trigger. The handle and disc are parallel to each other for that reason. The blade guard keeps your hand safe from the rotating blade, and there is usually another handle, which allows you to have a firmer grip while using the powerful tool.

The ergonomic design provides complete control and reduces fatigue. However, the angle grinder is larger than a cut-off tool and will wear your arms down faster. However, the angle grinder is very versatile and can be used for sharpening and polishing metals.

They are used extensively in automotive shops and can quickly cut through the metal parts of cars. Woodworkers and plumbers also use them; they can easily cut through wood and are great for cutting through pipes. Because of these design features, the angle grinder is more expensive than a cut-off tool.

- Versatile

- Powerful

- Ergonomic design

- Larger discs available

- More expensive

Material Size

The main difference between these two machines is the type of metal they can cut. Cut-off tools cut thin pieces of metal and are excellent for detailing small projects. Plus, they’re cheaper. So, if you only deal with smaller applications, you’ll be saving money by choosing a cut-off tool.

On the other hand, cut-off tools can’t handle larger jobs. They are not suitable for cutting through pipes or bars. Instead, you need an angle grinder in those situations.

Angle grinders are also more versatile than cut-off tools, so you can do more with them. If you work with various metals, you should use an angle grinder.

Cost

Angle grinders cost more than cut-off tools. However, that does not mean you should skip them entirely. Angle grinders can also replace hand tools, tile-cutting saws, and sanders, and they are incredibly versatile. Therefore, they may eliminate the need to buy other tools, saving you money in the long run.

There isn’t a huge price difference between the angle grinder and the cut-off tool, and you aren’t going to break the bank with either one. Furthermore, both of the tools have electric and pneumatic models, and their prices can range quite a bit. In some cases, the type of power it uses will dictate the cost more than anything else.

Portability

Cut-off tools are smaller and are the most portable compared to angle grinders. They’re ideal for working in small spaces. However, it is essential to remember that angle grinders aren’t too bulky, even if they aren’t as small as cut-off tools. Both tools are portable, but cut-off tools are usually much lighter.

Versatility

Angle grinders are some of the most versatile tools for construction projects. If you work with metal and wood frequently, an angle grinder is essential for large projects. On the other hand, cut-off tools are only suitable for thin metal. That makes them best for people who do a lot of work with thin metal.

Quick Look: Our Top Choices

| Image | Product | Details | |

|---|---|---|---|

Our Favorite Cut-off Tool

|

Milwaukee 2522-20 |

|

CHECK PRICE |

Our Favorite Angle Grinder

|

DeWalt Angle Grinder Tool |

|

CHECK PRICE |

Our Favorite Cut-off Tool: Milwaukee 2522-20

The Milwaukee 2522-20 can produce 20,000 revolutions per minute (RPM) for fast and accurate cutting performance. It has a reversible blade rotation for extra cutting control and a powerful brushless motor. The Redlink Plus Intelligence ensures the machine always performs optimally. Plus, it is backed up by the Milwaukee guarantee.

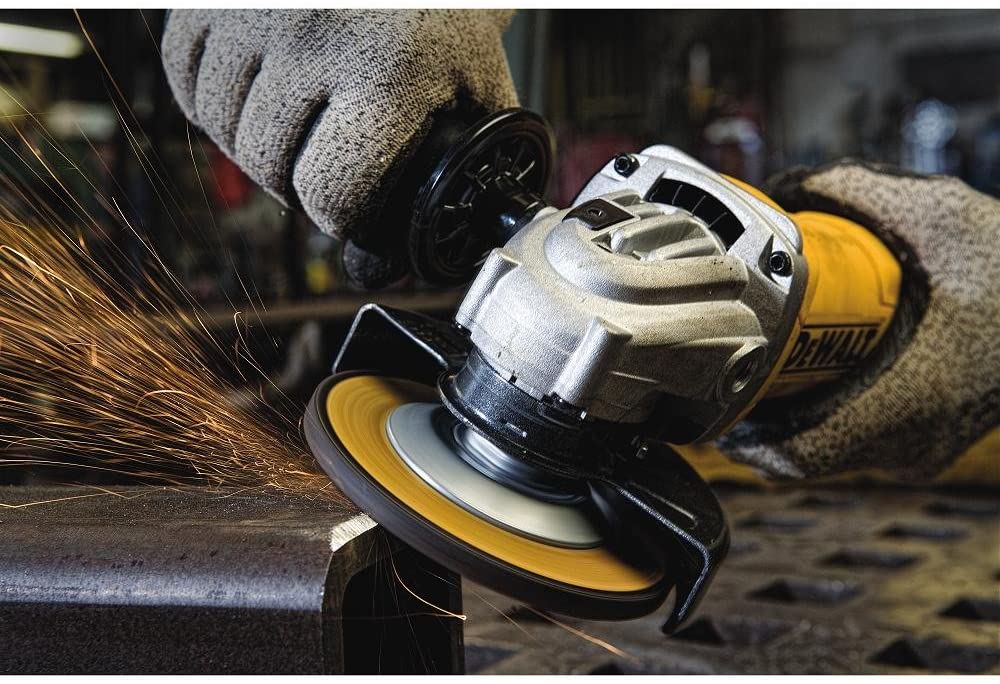

Our Favorite Angle Grinder: DeWalt Angle Grinder Tool

With an 11,000 RPM motor, the DeWalt Angle Grinder Tool is an excellent solution for most users. The dust ejection system provides enhanced durability since it ejects damaging dust from the motor. Simultaneously, the 2-position side handle helps ensure that you always have complete control over the tool.

Conclusion

For larger projects, you need an angle grinder. However, for small sheets of metal, you can use a cut-off tool. It just depends on the projects you have ahead of you! Home DIYers will usually get the most use out of an angle grinder, but if you often work with thin sheet metal, you need a cut-off tool. Angle grinders are usually more expensive than cut-off tools, but both tools are portable and easy to use.

- See also: 10 Best Air Cut-Off Tools

Contents